- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

Application and current situation of vitamin C:

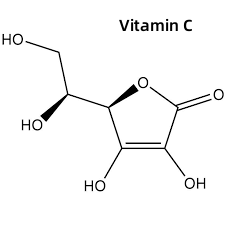

Vitamin C, also known as Ascorbic acid, is a white powder, odorless, sour, with a melting point of 190-192°C. It is easily soluble in water and methanol, slightly soluble in ethanol, and insoluble in ether, chloroform and petroleum ether. It has strong reducing properties and is easily damaged by light, heat, oxygen, etc. It decomposes faster in alkali solution or in the presence of trace metal ions, but is more stable after drying and crystallization. VC is an essential water-soluble vitamin for the human body and an antioxidant.

Vitamin C is one of the most produced and widely used varieties of vitamin drugs. Vitamin C plays an important role in medicine. It is an indispensable substance for maintaining human health. It is a catalyst for the redox reaction of living cells. It participates in various metabolisms in the body and has the physiological effect of promoting the synthesis of various hormones in the body. Lack of vitamin C in the body can cause scurvy, which can cause death in severe cases.

Vitamin C is both a drug and a nutritional supplement, and has been widely used in the food and cosmetics industries in recent years. At present, the annual consumption of vitamin C in the world is about 70,000 tons, and it is growing at a rate of more than 6% every year. With the improvement of my country's living standards and the increasing understanding that vitamin C increases human resistance and extends life span, the demand for vitamin C in my country is expected to increase significantly.

The effect of vitamin C crystal particle size testing on quality:

The industrial production of vitamin C is mainly based on the diketose method (also known as the Guessin method) and the two-step fermentation method. Since the diketose method has many reaction steps and requires the introduction of toxic substances during the production process, it is gradually being replaced by the synthetic process. At present, all domestic vitamin C manufacturers use a two-step fermentation process.

Crystallization is a very important unit operation in the pharmaceutical industry. This is because the crystallization process can form pure crystals from solutions with considerable impurity content (except for the formation of mixed crystals); according to statistics, more than 85% of pharmaceuticals end up as crystals. Form appears. In addition, the crystallized products have beautiful appearance and are very convenient for packaging, transportation, storage or use. Therefore, for many substances, crystallization is often the best and most economical method for large-scale production; on the other hand, for more substances, crystallization is also the most convenient method for small-scale preparation of pure products.

In the production of vitamin C, the crystallization process plays a key role in the quality of the final product. Especially for biochemical pharmaceutical products, the quality of crystal products, such as appearance, crystallinity and particle size distribution, will affect the stability of vitamin C products.

When the supramolecular structure of the crystal changes, it may produce different medicinal effects or even be toxic. The particle size distribution of crystals and crystallization also affect the efficacy of drugs. Drugs with different uses have different requirements for particle size distribution. Cooling control for solution crystallization is also very important. Different cooling controls directly affect product quality, such as the main particle size, particle size distribution and variation coefficient of the product, and even affect the crystal habit of the product.

Crystal particle size distribution, crystal shape and stability are the main parameters for evaluating the quality of crystallized products, so the detection of vitamin C crystal particle size is particularly important in the industrial production of vitamin C.

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer