- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

1. Soybean flour

Soy flour is soy flour made from defatted soybeans. Soy flour has high soy protein content and high unsaturated fatty acid content. Regular consumption has anti-aging, brain-building and other health effects.

Defatted soybean flour is a powdery product processed from soybean cake after oil extraction. It is divided into two types: baked defatted soybean flour and low-denaturation defatted soybean flour. Defatted soybean meal is divided into high denaturation and low denaturation. The biggest difference between the two is the different protein dispersion index. Highly denatured defatted soybean meal can partially or completely destroy the anti-nutritional factors that affect the digestion and utilization of soy protein after heat treatment. It is mainly used in foods mixed with cereals, such as 75% durum wheat flour and 25% defatted soybean flour. Macaroni can increase the protein content of the product to 28-30%, and the protein efficacy ratio (PER) of pure wheat flour products increases from 1.27 to 2.39. Low-denaturation defatted soybean meal is usually obtained under "flash desolvation" or "vacuum desolvation" conditions, and has a high protein dispersion index (PDI) of 70 to 90%. Therefore, compared with highly modified soybean meal, defatted soybean flour produced from low-denatured soybean meal has better functionality and is widely used in the food industry. When the functionality of defatted soybean flour is mainly considered in some food formulations, low-denaturation defatted soybean flour needs to be used. Here we focus on the production process, product uses and product quality indicators of low-denaturation defatted soybean flour.

Defatted soybean flour has different uses due to different production methods. One is that after degreasing, it can be directly used as animal feed after high temperature. There is also low-temperature desolubilized meal. Because low-temperature desolubilized meal has high water-soluble protein, it can be used as raw material for various soy foods. Defatted soybean flour contains high levels of lysine and sugar. When added to baked goods, it can not only increase the protein content, but also act as reducing sugar during baking, turning the surface of the food into a golden color and making the food soft. . In addition, defatted soy flour is added to whiten the bread due to the action of lipase. Adding soybean flour to bread can extend the storage time, increase the volume and improve the eatability due to its strong water absorption capacity. Therefore, defatted soybean flour can be used as a raw material for soy milk powder, concentrated protein, isolated protein, and textured protein, as well as an ingredient in bread, meat products, beverages, and infant food.

2. The relationship between soybean flour particle size control and protein quality

After repeated studies on the crushing degree of defatted soybeans and the relationship between particle size and protein content, it was found that defatted soybeans with high protein content can be obtained by crushing defatted soybeans into a certain particle size and obtaining specific tiny particle components through winnowing. pink. It can be seen that the key to whether high-protein defatted soybean flour can be produced lies in crushing.

The production of high-protein defatted soybean flour requires crushing defatted soybeans into an average particle size of 5 to 20 microns. If the particle size is greater than 20 microns, high-protein components cannot be fully separated; if the particle size is less than 5 microns, non-protein components are easily mixed in, causing obstacles to subsequent particle size classification.

The grinder used to grind defatted soybeans is sufficient as long as the object to be grinded is not heated during the grinding process. Impact mills such as hammer mills, axial flow mills, and rotating plate mills are usually used. And the speed of the grinder and the processing time should be determined according to the chosen grinder. Usually the peripheral speed of the crusher is selected between 40 and 150 meters/second, and the crushing takes only a few seconds.

The crushed defatted soybeans must be subjected to particle size classification. When defatted soybeans containing soybean seed coats are used as raw materials, they must be screened before particle size classification. Use a 80 to 170 mesh sieve to screen out seeds with larger particle sizes. The skin is coarsely grained, and then the grain size is classified.

Particle size classification can use dry air flow classification devices, such as free vortex air flow classifiers, forced air flow classifiers, etc. These classification devices can be used to screen out particles in the particle size range of 5 to 10 microns. Soybean flour in this particle size range has high protein content, high yield, and is easy to obtain. This high-protein defatted soy flour is extremely versatile and is particularly suitable for processing hamburgers.

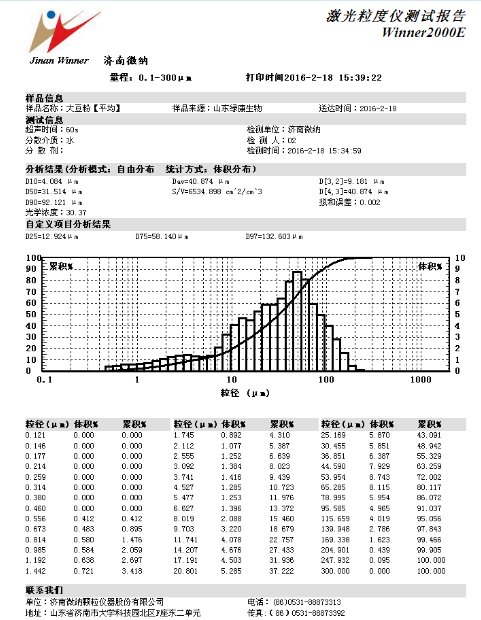

3. Application of laser particle size analyzer in particle size detection of defatted soybean flour

In the production and processing of defatted soybeans, particle size control is very important. As the most important modern particle size detection method, laser particle size analyzer is becoming more and more commonly used. This experiment used winner2000E, and the test report is as follows:

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer