- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

1. Nozzle and its industry development

The nozzle is called NOZZLE in English, and it is also called nozzle and nozzle in Chinese. The nozzle is a critical component in many types of spray, mist, oil injection, sandblasting, spraying and other equipment and plays an important role. Nozzles are widely used in the industry. The materials range from stainless steel and plastic to silicon carbide, polytetrafluoroethylene, PP (engineering plastics), aluminum alloy and tungsten steel. The application range is generally used in automobiles, electroplating, surface treatment, high pressure Cleaning, dust removal, cooling, desulfurization, humidification, mixing, gardening and other industries.

Since nozzles are designed to operate under a variety of different spray conditions, choose the nozzle that suits your needs to achieve the best spray performance during use. The characteristics of a nozzle are mainly reflected in the spray type of the nozzle, that is, the shape formed by the liquid when it leaves the nozzle mouth, and its operating performance. The naming of nozzles is based on the spray shape, which is divided into fan-shaped, cone-shaped, liquid column flow (i.e. jet), air atomization, and flat nozzles. Among them, cone-shaped nozzles are divided into two categories: hollow cone and solid cone; choose a nozzle The factors include flow, pressure, spray angle, coverage, impact, temperature, material, application, etc., and these factors are often involved and restrictive of each other.

In recent years, China's spray industry has grown steadily, and the nozzle and nozzle industry has become increasingly important. At present, the development of the nozzle industry has entered a stage of change, which is the stage of upgrading of China's hardware products, a transition period from low-end to high-end products. The market demand for spray parts is huge. Due to the improvement of China's hardware manufacturing level and the expansion of production capacity, it is expected that China's hardware products will maintain a steady growth of more than 10% per year in the next five years.

2. Why does the nozzle need to be sprayed?

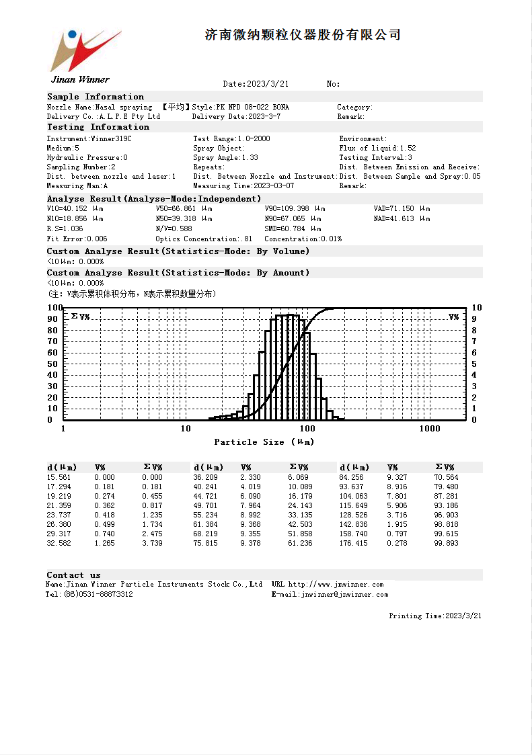

Atomizing liquids is a common need in many professional fields. Various liquid atomizers are used in air-conditioned spray rooms, agricultural plant protection machinery, atomized cooling and spray disinfection in agricultural buildings, sprinkler irrigation and spray drying. An important indicator for evaluating the performance of a nozzle is the droplet diameter and droplet diameter spectrum distribution it produces. Although commonly used evaluation indicators such as quantitative diameter, volumetric diameter, arithmetic mean diameter or Soter mean diameter can be determined from different The side surface reflects the overall droplet diameter, but cannot fully reflect the overall droplet diameter distribution, that is, the range of droplet diameters and the small proportion of droplets of different diameters. In order to conduct in-depth research on nozzles, in order to correctly use and design nozzles and related devices that match them, it is necessary to fully understand the overall distribution of droplet diameter spectra.

Determination of nozzle spray particle size index The fog field formed by nozzle spray is composed of droplet group particles of different sizes. In order to describe and evaluate the atomization quality of the droplet group and express its atomization characteristics, a droplet size distribution expression is needed To measure the particle diameter or the quantity or quality of particles of different diameters. The index for evaluating droplet size can be expressed by a so-called "average diameter", which assumes a fog field with uniform droplet size. Its characteristics in certain aspects can replace the characteristics of the actual uneven fog field. This The droplet size of the envisaged uniform fog field is called the average particle size.

3. Spray particle size measurement method

Method for measuring droplet size:

The accuracy of droplet size testing is closely related to the droplet sampling method and the accuracy of the measuring instrument. The ideal droplet measurement accuracy should achieve: rapid sampling and measurement; good droplet size resolution within the entire measured range; ability to adapt to changes in the liquid atomization zone and surrounding air characteristics; no interference during the measurement process Atomization process or spray characteristics; convenient measurement and good economy. Moreover, a large number of methods for measuring droplet size have been developed so far, and none of them can meet all the above conditions. The key is to find a measurement method that meets the needs of specific fields.

Foreign research on droplet size measurement experiments started early. For example, in the early 1940s, Meginer began to use the spot method to directly measure the size and distribution of droplets. Later, Hoffman's photography method was an improved method of directly measuring the size and distribution of fog droplets. Because the experiment cycle is long and requires the participation of professionals, and the workload is huge, few people use this method. Considering that the mist droplets are tiny and easy to evaporate, Tate once proposed using immersion technology to collect mist droplets. Since water droplets are incompatible with low-density oil, water droplets falling into the oil will be surrounded by the oil to avoid evaporation. , due to the tension on the surface of water droplets, a microscope can be used to measure the size of the droplets. At this stage, a microscope is mainly used to manually measure the droplet size, which requires a large workload and poor accuracy.

When the droplet size is too small, the droplets are highly volatile and drift a lot, making it difficult to measure accurately. Therefore, in order to more accurately measure the size and distribution of droplets, many optical-based measurement systems have been invented, among which the laser particle size analyzer is one of the representatives. When particles dispersed in a liquid are irradiated by laser, diffraction occurs. After passing through the Fourier lens, the diffracted light forms a "bullseye"-shaped diffraction halo on the focal plane. The radius of the diffraction halo is related to the size of the particles. The intensity of the diffraction halo is related to the number of particles of relevant particle sizes. By placing a ring-shaped photoreceptor array on the focal plane, the diffraction signals or light scattering signals of particles of different particle sizes can be received. This instrument has extremely high measurement accuracy. Due to the use of laser technology for non-contact measurement of fog droplets, the measurement error is reduced to a very low level. When the diameter of the droplets is 1 micron, the error is no more than 4%, and the measurement values require almost no correction; The automobile measurement process is extremely fast and simple. The measurement of fog droplets in the air does not take more than a few seconds. The measurement results can be quickly printed after computer processing; the measurement results can be quickly printed out after calculation and processing; the measurement range can reach 0.5 Micron - 3500 micron. This range is unreachable by manual measurement. With the development of modern technology, laser particle size analyzers currently being developed abroad can also measure the speed of fog droplets.

4. Application of laser particle size analyzer in the nozzle industry

The laser particle size meter is a new type of particle size detection equipment that has emerged in recent years. Its real-time detection characteristics enable it to have a wide range of applications. With the development of nozzle testing technology, the application of laser particle size analyzers in spray experiments has received more and more widespread attention. State Key Laboratory of Coal Combustion, Wuhan University of Science and Technology,

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer