- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

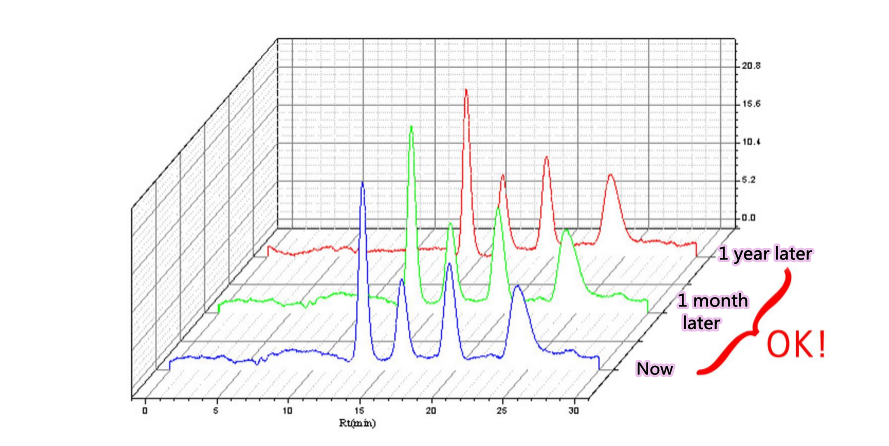

The significance of reproducibility evaluation has the following aspects, one is used to understand the long-term stability of the instrument; the other is used to evaluate the stability of the sampling method; the third is used to evaluate the standardization of operation; the fourth is used to evaluate the instrument Consistency of parameter settings; Fifth, it is used to evaluate the impact of the environment on the instrument. Standard samples should be used for reproducibility evaluation. The standard samples can be certified standard samples, working standard samples attached to the instrument, or those kept by the user themselves. Experience is a qualified product. But no matter what kind of sample is used, it must be ensured that the sample is stable and unchanged. The reproducibility is generally evaluated every three months.

Compare the results of this evaluation with the previous results. If the reproducibility is within the allowable range of error, it means that the instrument, sampling, operation, parameters and environment have not changed. The result is objective and effective, otherwise it is necessary to find out the reason and deal with it.

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer