- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

What is the meaning of "mesh" in how many mesh screens does the sample pass through?

Mesh is a way of indicating the size of the screen, and the number of holes per inch of screen is called how many "mesh". The larger the mesh, the smaller the mesh. Countries have different standards for sieve size, so the meaning of "mesh" is not the same. Now the international standard screen, basically using the Taylor screen system, with 200 mesh as the benchmark, the series of two adjacent screens, the sieve size compared to, that is, the sieve area is twice the difference.

What is a microsieve?

Screens with more than 400 mesh are called microporous screens, which are rarely used in academia and commonly used in industry, so there is no international standard. According to the Japanese standard, microporous screen specifications are shown in Table 4:

Table 4 Microporous sieve specifications :

Mesh | Size (µm)

| Mesh | Size (µm)

|

400 | 37/34 | 1500 | 10/8 |

500 | 34/28 | 2000 | 8/6 |

600 | 28/24 | 2500 | 6/5 |

700 | 24/20 | 3000 | 5/4 |

800 | 20/16 | 4000 | 4/3 |

1000 | 16/13 | 6000 | 3/2 |

1200 | 13/10 | ------- | -------- |

What is the principle of light penetration particle size testing?

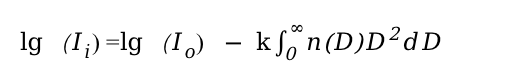

According to Stokes' law, the particle size can be obtained by measuring the settling velocity of the particle. In the actual measurement process, it is difficult to directly measure the settling velocity of particles, so the change rate of light intensity through suspension with time is often used to indirectly reflect the settling velocity of particles in the process of particle size measurement by sedimentation method. According to Beer's law, the quantitative relationship between light intensity and particle size at a certain time is:

In this way, we can get the change rate of light intensity by measuring light intensity at different times, and the particle size distribution can be obtained.

What is the testing principle of image granularity analyzer?

The particles are imaged on an imager, and the smallest units that make up the image are pixels, each of which has a specific size. Image granularity analyzer is to calculate the area of each particle by counting how many pixels it occupies in the image, and then calculate the diameter of the circle of equal area.

What are the differences between dynamic imager and static imager?

Compared with static imager, dynamic imager has the advantages of easy particle dispersion, no orientation error, large sampling volume and good representativeness. However, this method is easy to tail the moving image, the image quality is also poor, can not see the particle morphology, and also requires high-speed processing and analysis system.

What are the differences between dynamic imager and static imager?

Compared with static imager, dynamic imager has the advantages of easy particle dispersion, no orientation error, large sampling volume and good representativeness. However, this method is easy to tail the moving image, the image quality is also poor, can not see the particle morphology, and also requires high-speed processing and analysis system.

What is the test principle of laser particle size analyzer?

According to the principle of laser scattering, the distribution of scattered light energy with the scattering Angle is different depending on the particle size, and this distribution is called scattering spectrum. The laser particle size analyzer is used to retrieve the particle size and its distribution by detecting the scattering spectrum of particle groups.

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer