- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

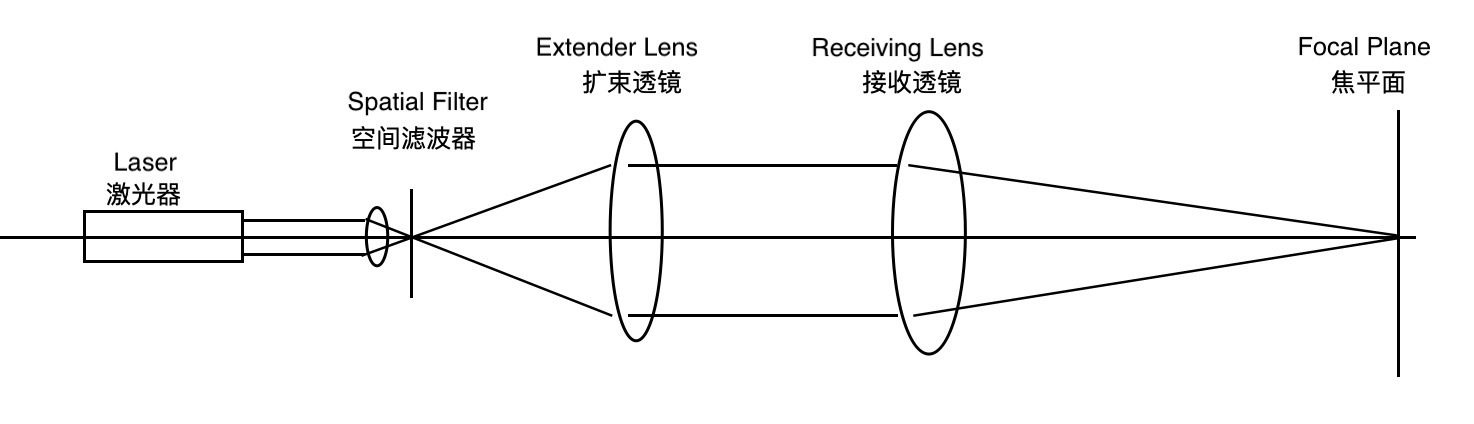

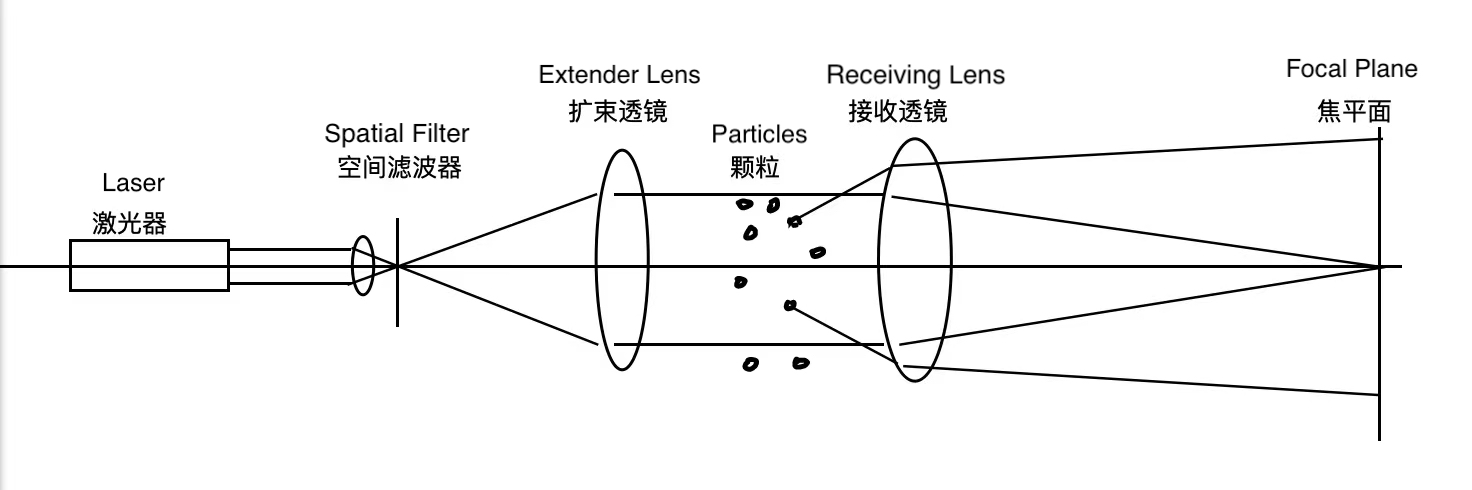

The laser particle size analyzer is generally composed of laser, Fourier lens, photoreceiver array, signal conversion and transmission system, sample dispersion system, data processing system and so on. The laser beam emitted by the laser is filtered, expanded, and collimated into a parallel beam. Without the parallel beam shining on the particle, the beam passes through the Fourier lens and converges it to the focus. When the particles are uniformly placed along the parallel beam path in a certain way, the laser beam passing through the particles will be diffracted or scattered, and part of the light will be scattered outward at an Angle to the optical axis (as shown in Figure 1). It is proved that the scattering Angle between the light emitted by large particles and the optical axis is small, while the scattering Angle between the light emitted by small particles and the optical axis is large. These different angles of dispersion

The light that passes through the lens converges on the focal plane to form rings with different radii and alternating shades. These rings with different radii contain information about particle size and content. The particle size distribution can be obtained by installing a series of photoreceivers radially on the focal plane, converting the optical signals into electrical signals and transmitting them to a computer, and then analyzing and recognizing these signals with special software.

How to judge whether the optical system of laser particle size analyzer is normal?

(1) First observe the background, the center of the first ring height should be within the specified range: the second ring height should be significantly lower than the first ring height: after the height of the rings should be smooth and continuous; There is no obvious fluctuation in the background signals.

(2) Secondly, add powder sample, observe whether the instrument energy spectrum signal response is fast, continuous energy spectrum, no fluctuation jump.

(3) For the instrument equipped with a self-checking system, the self-checking system will automatically detect the state of the instrument and give the operation prompt.

What is shading rate? How many is the best shading rate of laser granularity instrument?

The shading rate can be defined as the ratio of the shading cross section of the particles in the beam to the total area of the beam, usually expressed by the percentage of the light scattered and absorbed by the particles in the total output light (minus the background scattering). Therefore, shading rate is also known as optical concentration. The specific calculation method is to divide the difference between the light intensity of the detector center point after laser penetration of pure medium and the light intensity of the detector center point after adding the sample by the light intensity, that is, refraction rate = (-) /×100%, usually the best shading rate of laser particle size analyzer is between 10% and 15%.

The optical concentration is different from the volume (mass) percentage concentration of the particle. The former is related to the particle size. The smaller the particle, the larger the specific surface area, the stronger the shading ability. Therefore, the smaller particles of two samples with the same volume concentration will show a larger optical concentration in the laser particle size analyzer.

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer