- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

Winner2309A is intelligent full automatic laser particle size analyzer,adopt the most advanced International MIE scattering principle and Fraunhofer diffraction principle, which is integrated model of wet and dry dispersion system, High sensitive and High-resolution photoelectric probe system and imported Canon lens optical path ensure the good accuracy and repeatability of particle size distribution, It’s widely used in industrial production quality control departments and research institutions.

Products Description

1. Main Specifications: (sample cuvette is available)

Model Name | Winner2309A | |

Standard and conformity | ISO13320-1:2009,GB/T19007-2016,Q/0100JWN001-2024 Compliance with 21 CFR Part 11, CE. | |

Principle | Laser light scattering | |

Analysis | Mie and Fraunhofer scattering | |

Detector Arrangement | Log-spaced array, test angle from 0.015 degree to 145 degree | |

Red Light source | Max.4.0MW Fiber, 639nm | |

Optical path | Reverse Fourier(Folded optical path) | |

Laser Safety | Class 1 | |

Measuring Range | Wet:0.01μm-3500 μm Dry: 0.1μm-3000μm | |

Silicon Photodetectors | Wet:116 pcs Dry:116 pcs | |

Accuracy error | Wet<0.6% Dry<0.6% (CRM D50) | |

Repeatability error | Better than 1% variation, Better than 1% variation | |

Reproducibility error | Better than 1% variation, Better than 1% variation | |

Wet dispersion | Ultrasonic | Frequency:40KHz Max Power:60W, ultrasonic time:adjustable |

Stir | Revolutions Speed: 0-3000RPM (Adjustable) | |

Circulate | Rated Flow:1L-8L/min Rated Power:120W | |

Anti-overflow sensor (UK) | Prevent water overflow and effectively protect the instrument | |

Sample tank | Volume:600mL | |

Micro-Sample cuvette | Volume: 10mL ( optional), suitable for testing precious samples and corrosive samples. | |

Dry dispersion | Dry-turbulence dispersion patent technology, normal shock wave shear technique | |

Feeding Speed | Adjustable (Variable speed knob) | |

Operation Mode | Full automatic / manual control, freely choose | |

Dispersion medium | Compressed Air, pressure: 0 to 6 bar | |

Optical bench alignment system | Full automatic, precision is up to 0.2um | |

Full Test Speed per time | Wet: <2 Min Dry : <1min Inverval time per test result :500ms | |

Outer dimension | L87×W37×H33cm , L44*W35*H38cm | |

Environmental Requirement: | Temperature: 5-35℃ Humidity:<85% | |

Storage temperature | -20°C to +50°C | |

Net Weight | 32+15 KG | |

2. Main Features:

1)Wet and dry, unique separated dispersion module.

The instrument adopts a modular design for automatic dry and wet dispersion. Customers can freely assemble it according to the test requirements of sample characteristics. It is simple, convenient and fast.

2) Operation mode:

Intelligent full automatic operation system and manual operation, freely choose.

Choose automatic mode, very easy and simple to learn,support SOP operation.

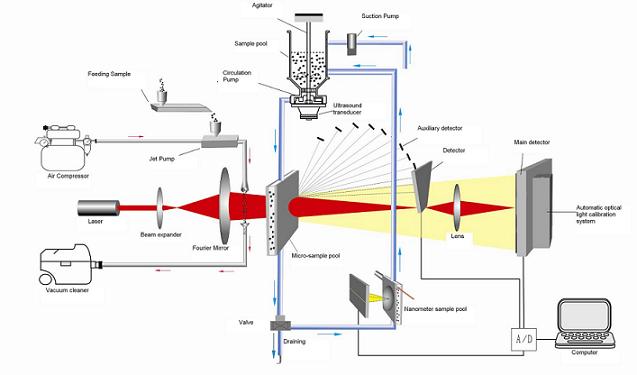

3) Optical path design:

Adopting the patented inverse Fourier (folded optical path) technology, the reception of scattered light from sample particles is not limited by the focal length of the optical path. The test angle range is 0.015-145 degrees, which effectively improves the measurement range and the resolution of the instrument. The optical path is sealed and has good dustproof performance.

4) Automatic Optical path alignment System,

which is composed of precise four phase hybrid stepper motor, Its inching precision is reach to micron level,make optimum optical paths to ensure accurate and stable test.

5) Automatic sample dispersion system.

The modular design of dry and wet dispersion shortens the circulation pipeline and prevents the precipitation of large particles. It is not only conducive to the uniform dispersion of samples, but also reduces maintenance costs and is conducive to the cleaning and maintenance of equipment.

6)Instrument Software

The unique unconstrained free fitting technology collects scattering data during the measurement process and has the ability to automatically analyze multi-modal particle groups. It is not constrained by any function. The analysis result depends entirely on the distribution of the scattering spectrum, which maximizes the fitting accuracy and truly reflects the particle size distribution of all samples. Particles below 2μm are tested in 12 particle size grades with extremely high physical resolution.

3. Software Function:

1, Analysis Mode

Free Distribution, R-R Distribution, Logarithm Normal Distribution, Mesh number classification etc. meet different demands of particle size statistic in different industries.

2,Statistic Method

Volume Distribution, Quantity Distribution

3,Statistic Comparison

Statistic Several Testing Results to compare and analyze

Get difference by compare test result of different batches of samples, samples before and after processing, and different time.

Have great practical significance to industrial raw materials quality control

4,User-defined Analysis

Figure out percentage according to the particle size

Figure out particle size according to the percentage

Figure out percentage according to the particle size range

Meet demands of representation of particle test in different industries.

5,Test Report

Word, Excel,Photo( Bmp), Text etc.

6,Multi-language Support

Chinese&English (Others are available)

7,Intelligent Operation Mode

Automatically control water inflow, dispersion,test and analysis.

Better Repeatability after remove human-factor

SCHEME:

4. Application:

Solid powder, suspension and emulsion.Chemicals, Magnetic Materials, Medicine, Cement, Coatings, Food, Pesticides, Nuclear Industry, Electronics, Battery Materials, Paper, Metallurgy, Ceramics, Building Materials, Cosmetics, Abrasives, Metal and Non-metal Powders, Calcium Carbonate, Talc, Kaolin, Oxidation Particle size testing of powders in their respective industries such as aluminum, rare earth, cemented carbide, catalysts, foaming agents, refractory materials, fillers, graphite, pigments, etc.

5. Patent Technology:

1. Optical bench design is protected by patent No.- ZL 2014 2 0378380.8,

2. Three dimensional-optical bench alignment system is protected by patent No.- ZL 2013 2 0835882.4.

3. MIE scattering principle application patent No.- ZL 2013 2 0812021.4.

4. Dry particle size analyzer full sealed sample cuvette application is protected by patent No.- ZL.2011 2 0267646.8.

5. Dual laser beam orthogonal application is protected by patent No.-ZL 2007 2 0025702.0

6. Powder dispersion pump design application is protected by patent No.-ZL 2007 2 0018648.7

7. Wet circulation installation is protected by patent No.-ZL2010 2 0593526.2

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer