- Call us!

- +86 531 8887 6213

- cathy@winner-psa.com

Currently, the structural contradiction of severe overcapacity in cement production across the country still exists, and the task of energy conservation and emission reduction in the cement industry remains arduous. With the goals of carbon peaking and carbon neutrality proposed, the cement industry is bound to step up efforts to eliminate backward production capacity and accelerate the pace of energy conservation, environmental protection, and digital and intelligent upgrading. Cement grinding occupies a pivotal position in cement production. How to adapt to the needs of the situation, achieve deep integration with digitalization, intelligence and networking, transform and upgrade, and achieve high-quality, green and low-carbon development are urgent issues currently faced.

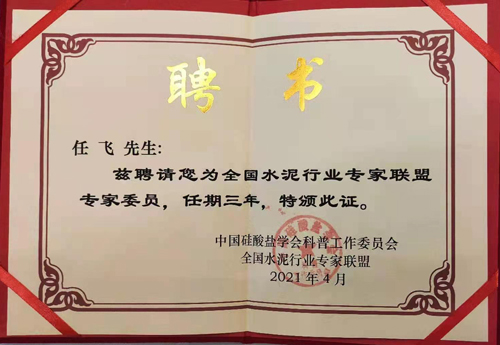

The 2021 13th Domestic and Foreign Cement Grinding New Technology Exchange Conference, co-organized by the Science Popularization Working Committee of the Chinese Ceramic Society, the Building Materials Industry Technical Information Institute, and the National Cement Industry Expert Alliance, was held in Meizhou, Guangdong. Cement production in various provinces and cities across the country More than 400 people including leaders, experts, scholars, and technical backbones from enterprises, grinding stations, scientific research/design institutes, colleges and universities, equipment manufacturers, commercial concrete mixing stations (those with own grinding workshops), associations, societies, etc. attended the meeting At this conference, we conducted in-depth exchanges and discussions on hot issues such as how the cement grinding system can achieve high quality, high efficiency, green and low carbon, and improve corporate competitiveness through technological innovation, transformation and upgrading, and high-end intelligence. Jinan Winner Particle Instrument Co., Ltd. was invited to participate. Jinan Winner brought the winner1702 online particle size monitoring system to this meeting. The technology helps cement particle size and quality control. Mr. Ren Fei, chairman of Jinan Winner, attended the meeting and gave a report. In addition, Mr. Ren Fei was also hired as an expert member of the National Cement Industry Expert Alliance.

The 2021 13th Domestic and Foreign Cement Grinding New Technology Exchange Conference, co-organized by the Science Popularization Working Committee of the Chinese Ceramic Society, the Building Materials Industry Technical Information Institute, and the National Cement Industry Expert Alliance, was held in Meizhou, Guangdong. Cement production in various provinces and cities across the country More than 400 people including leaders, experts, scholars, and technical backbones from enterprises, grinding stations, scientific research/design institutes, colleges and universities, equipment manufacturers, commercial concrete mixing stations (those with own grinding workshops), associations, societies, etc. attended the meeting At this conference, we conducted in-depth exchanges and discussions on hot issues such as how the cement grinding system can achieve high quality, high efficiency, green and low carbon, and improve corporate competitiveness through technological innovation, transformation and upgrading, and high-end intelligence. Jinan Winner Particle Instrument Co., Ltd. was invited to participate. Jinan Winner brought the winner1702 online particle size monitoring system to this meeting. The technology helps cement particle size and quality control. Mr. Ren Fei, chairman of Jinan Winner, attended the meeting and gave a report. In addition, Mr. Ren Fei was also hired as an expert member of the National Cement Industry Expert Alliance.

At present, the Winner online particle size monitoring system has been tested on the production line of a large domestic cement company and has shown that the system is intelligently operated, simple and convenient, greatly reducing the labor intensity of staff and saving labor costs. Exclusive maintenance-free design, no need to disassemble and clean in the later stage, and no wearing parts. Get test data in real time and adjust production at any time. Through particle size detection and analysis, the usage status of the mill can be detected. It plays a very important role in improving product quality and reducing energy consumption in cement

Copyright © Jinan Winner Particle Instrument Stock Co., Ltd. All Rights Reserved | Sitemap

Keywords:

Laser Particle Size Analyzer Spray Particle Size Analyzer Particle Image System Online Particle Size Analyzer Particle Size Analyzer particle size distribution particle size analyzer manufacturer Laser diffraction particle size analyzer particle size malvern particle size analyzer